DryiceInfo

The Authentic History of Dry Ice

Dry Ice History

A French chemist, Thilorier was likely the first to record the appearance of solid CO2 – dry ice. In 1835 he opened a cylinder with a large amount of liquid carbon dioxide to observe it in liquid form. Enough of it evaporated to leave a solid dry ice block at the bottom of the container.

Many chemists of the early 1800s experimented with gasses and realized that to keep them in liquid form, they needed a more robust container than glass which often broke under the high pressure required to keep the gasses liquid. Thilorier and others tried more substantial metal chambers. Metal vassals worked to keep CO2 at 63 times normal atmospheric pressure but hid the liquid from view. Thilorier realized that he could observe the color and viscosity of the liquid CO2 by creating a more significant amount of liquid CO2. When he opened the metal chamber, the liquid rapidly boiled off before being observed.

For the next 60 years, it was observed in university labs but not used for any practical applications. Even today, anyone can take a metal cylinder of liquid CO2 (like a CO2 fire extinguisher), open the valve, and observe the escaping gas cloud with part of it turning into dry ice powdered snow.

In 1897 a patent was granted in England to Herbert Samuel Elworthy, a British Army Medical Corps doctor, to solidify carbon dioxide. His purpose was to make soda water to mix with his whisky. Liquid CO2worked fine, but the metal cylinder bottles were too heavy to take on excursions. A 100-pound cylinder carried only 50 pounds of CO2. He preferred to make solid dry ice for his soda water. Unfortunately, the dry ice didn’t last long as it sublimated into gas before being used. After that, few used dry ice for this patented purpose. A few doctors used dry ice to remove warts from time to time.

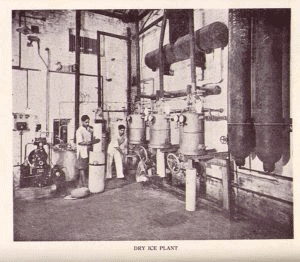

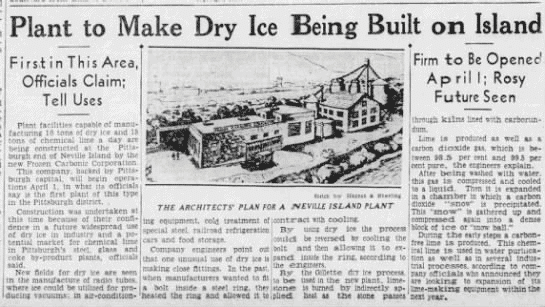

The first commercial use for dry ice in the United States was started in 1925 by Prest Air Devices, a company formed in Long Island City, New York, in 1923. Thomas Benton Slate, the inventor, and co-owner of Prest Air Devices, made solid dry ice for demonstration purposes. Prest Air Devices made the first CO2 fire extinguisher and tried many other uses for compressed CO2, such as a tire pump, powering grease guns, and making soda water in the home. Only the fire extinguisher worked well enough to market successfully. But it wasn’t until Mr. George C. Cusack and Mr. A. J. Whaley joined the company in 1924 and tried to sell dry ice to the railroad companies to cool in place of ice. Dry ice has twice the cooling power as water ice so it is far more efficient. Based on the potential railroad business Mr. August Heckscher invested the money to build a dry ice production plant. In 1925 Mr. Slate left the company for the west coast and made a better dirigible. The successful Prest Air Devices were sold, and the company was incorporated as DryIce Corporation of America, trademarking the name DryIce in 1925. They tried to patient dry ice again but were successfully challenged and turned down by the US Supreme Court.

The first dry ice test for railroad cars by DryIce Corporation was successful, and by 1932 there were twelve cars insulated properly to handle dry ice. There were also about eighty cars with mechanical refrigeration using a silica gel and 180,000 railroad cars designed to use regular ice for refrigerated goods. Unfortunately for the early dry ice producers, mechanical refrigeration won out for the railroad car business. The railroads invested and sometimes owned many water ice plants on their property. However, some railroad cars in 2004 still use regular water ice to cool carrots shipped from California.

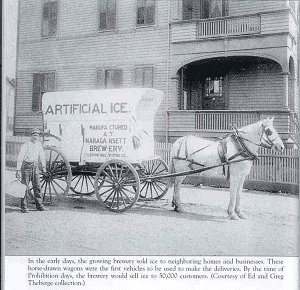

In 1925, DryIce Corporation of America produced dry ice without any customers. Their first customer in 1926 was Schraff’s Stores – a confectionary store that sold Eskimo Pie ice cream and other items. Schraff’s experimented with packaging to keep the ice cream cold so a customer could eat it at home instead of at the store. Dry ice was the solution. Before dry ice, salt was added to water and then frozen. This colder “brine ice” would keep ice cream frozen when distributed to the retail stores. The melting brine ice was corrosive, wet, and heavy. Dry ice became the ideal solution, and by 1927 many ice cream manufacturers, including Breyers Ice Cream, were using DryIce Corporation of America to ship and store their ice cream.

DryIce Corporation of America teamed up with Liquid Carbonic in 1929 to build 17 dry ice manufacturing plants across the US, including Los Angeles, California. Before the plants were finished, DryIce Corporation and Liquid Carbonic dissolved their agreement and went their separate ways, becoming competitors. Birdseye Frozen Foods started in 1931 and immediately used dry ice for transporting their samples to promote their products. By 1932 with six or seven other dry ice manufacturers, the estimated US production was 120,000,000 pounds.

In 2021, with the production of a vaccine for Covid 19, Phizer uses dry ice worldwide to distribute its vaccine, which must maintain a temperature of -94°F and stored in dry ice or an Ultra-Low-Temperature (ULT) Freezer -130°F to -76°F (-90°C to -60°C).

Today there are thousands of dry ice producers all around the world. Many sell to the public, but many also manufacture dry ice for their use, such as Disney Land.

DRYICE CORPORATION OF AMERICA

Description of Product:

DryIce is frozen carbon dioxide-the gas that is in all carbonated beverages. It is similar to a white water ice in physical characteristics, only very much colder.

Its temperature is about 114 degrees below zero, Fahrenheit (-80 C.) but because it evaporates to a gas it can be readily insulated with various thicknesses of insulation to cool its surroundings to any desired temperature above this point.

DryIce melts to a dry gas, heavier than air, and is mildly sterilizing in effect. The rate of melting is remarkably slow.

It Is Dry:

There is no drip; the evaporation is a dry, harmless gas. This permits shipment of perishables by mail of express in non-returnable paper boxes. There is no water or moisture to damage the article being shipped.

Its dryness eliminates the expensive pick-up of “empties” and permits a much greater proportion of the load capacity to consist of the material to be refrigerated.

If you have a refrigeration problem look into DryIce. It may save you a capitol investment.

1. What is it?— Solid carbon dioxide CO2 – the same harmless gas used to charge all carbonated beverages.

2. Why is it called DryIce?— Because it evaporates to dry harmless gas. There is no moisture or water.

3. How cold is it?— 114° below zero or 146° colder than water ice.

4. What does it look like?— A block of white marble.

5. How long does it last?— In an approved storage box, it will lose about 10% of its weight each 24 hours. A forty-pound piece placed uncovered in a store window in midsummer will last about 28 hours; in an approved storage box, from one to two weeks.

6. How is DryIce kept? — In a balsa-wood storage box. A balsa box having a DryIce capacity of 200 pounds costs approximately $25.00.

7. Why is a Balsa-wood box used?— Because balsa wood insulates as well as cork board, is considerably lighter, and requires no metal lining.

8. How is it shipped?— In solid blocks 10″ x 10″ x 10″, weighing approximately 40 pounds each. These blocks are shipped in a balsa-wood box, containing 200 pounds. The weight of the box is about 100 pounds. The cost is $30.00 to $45.00. The ice is removed from the shipping box, placed in a storage box, and the shipping box returned by express. Shipments for points outside New York are made by express; deliveries in New York City by trucks.

9. What does DryIce save?

(a) Weight — An equal amount of ice cream packed by the DryIce method weighs only 1/4 as much as if packed the old fashioned way. This cuts shipping and delivery costs to a minimum.

(b) Corrosion — When DryIce is used corrosion is eliminated. This of course is due to the lack of moisture. Because of this important feature, the repair bills on truck bodies or refrigerator cars are greatly reduced.

(c) Dampness and Damage — A wet and sloppy condition necessarily exists whenever ice and salt are used. Brine leakage causes untold damage particularly in connection with express shipments. Caterer’s customers and apartment dwellers object to sloppy ice pails and welcome DryIce packing.

(d) Delivery Expense — Light dry “one-time” or “throw-away” packages eliminate loss, upkeep, and the expense of picking up empty containers.

(e) Cabinets — There are no power bills — no water bills, no service charges nor breakdowns — no fire nor explosion hazard, as in mechanical refrigeration.

(f) Investment — Initial cost reduced to a minimum. The DryIce box is inexpensive. Depreciation no greater than any other store fixture. Installation as simple as placing a desk. Can be set anywhere.

10. How is it being used at the present?— For the refrigeration of perishables in transit. For instance, ice cream is being successfully packed with DryIce to keep firm for any period from 2 hours to 6 days, depending on the type of container and the amount of ice used.

11. What kind of container is used for delivering ice cream packed with DryIce?

(a) Corrugated cartons of approved types are recommended. The use of the carton eliminates the necessity of ice, salt and tub.

(b) Other containers; shipping jackets, bags, and insulated shipping boxes.

12. How is DryIce applied to these packages?

Pints — Your regular carton is placed inside an approved corrugated container. One-half pound of DryIce in a paper bag is placed on top inside box and the package sealed securely with gummed tape. This will hold the cream firm for 6 to 8 hours.

Quarts — Follow the same procedure except 3/4 of a pound of DryIce is required to keep cream firm for 6 to 8 hours.

4 Quarts — Follow the same procedure except 2 pounds of DryIce is required to keep cream firm for 6 to 8 hours. If cream is to be kept for 12 hours place 1 pound of DryIce on bottom of carton in addition to the 2 pounds on top.

8 Quarts — Place 1 1/2pounds of DryIce in bottom of corrugated carton, the box of cream on top of this, and put 2 1/2 pounds of DryIce in a bag on top of cream. Carefully seal the carton. This will hold contents for 12 hours.

3 and 5 Gallon bulk shipments — We have developed a “one-time” or “throw-away” ice cream can for these shipments, which when used in conjunction with DryIce and corrugated cartons of approved type, eliminates the expense and annoyance of handling tubs and cans which must be collected.

In packing 3 gallon shipmen, place 2 3/4 pounds of DryIce on top and 1 3/4 pounds of DryIce on bottom.

In packing 5 gallon shipments, place 3 pounds of DryIce on bottom and 4 pounds of DryIce on top. Wrap ice in 3 thicknesses of ordinary wrapping paper, can and ice bag.

Jackets or Bags — 3 to 4 pounds of DryIce placed in paper bag and put on top of ice cream 5-gallon can, will insure firm ice cream for about 18 hours.

Shipping Boxes — Ice cream may be kept for days in insulated shipping boxes. New York ice cream manufacturers are shipping their products anywhere East of the Mississippi by rail and regularly to Cuba and similar points by steamer.

13. Can DryIce be used for ice cream dispensing cabinets? — Most certainly! DryIce ice cream cabinets eliminate all plumbing connections, drains, etc. There are no repair bills, no machinery, no moisture to cause corrosion. This is the cleanest, lightest, and smallest ice cream box ever designed. The operating expense on these cabinets compares favorably with that of methods now in use.

14. What is the DryIce counter box? — A clean, light, dry box that takes up a minimum of counter space and can be attractively decorated for advertising purposes. For the first time in history of the ice cream industry it is possible to display boxes of ice cream on the dealer’s counter in full view of his customers.

15. What is the best way to cut DryIce to desired sizes? — The most convenient method of cutting is with a power band saw. (sic. still used today) However, in many cases where the amount of ice cream packing would not warrant the installation of the power saw, a rough toothed hand saw is used.

To make small blocks of DryIce place a sharp blow with hammer. (sic. using goggles) Since the weight of DryIce is uniform (.038 lbs. per cubic inch) the operator very soon learns to estimate the proper amount of ice for the desired result. The more it is broken up the greater the evaporation.

For your information:

7x7x 3/4 weighs 1 1/2 pounds approximately

7x7x 1 weighs 2 pounds approximately

7x7x 1 3/4 weighs 2 1/2 pounds approximately

7x7x 1 1/4 weighs 3 pounds approximately

16. Who is using DryIce now? — Space does not permit listing all of our customers. A few, however, are:

Abbotts Alderney Dairies, Inc.

Breyers Ice Cream Company

Burdan Bros.

Consolidated Dairy Products, Inc.

Crane Ice Cream Co.

Colonial Ice Cream Co.

Hydrox Corp.

Horton Ice Cream Co.

Huylers

New York Eskimo Pie Corp.

Maresi Mazzetti Corp.

Reid Ice Cream Co.

Louis Sherry, Inc.

John Wanamaker, etc.

17. How are caterers using DryIce? — For home delivery of ice cream and fancy forms. To deliver fancy forms, place the form in a carton, which with DryIce on top is placed in a corrugated shipping box.

The amount of DryIce used for this purpose varies from 2 to 5 pounds depending on the time which will elapse between putting up the package and unpacking.

18. What uses other than those described above?

Refrigerating Union News train baskets and boxes.

Serving ice cream in ball parks — outdoor gatherings —and factories.

Ice cream trucks.

Meat and fish shipments.

Meat and fish trucks.

Carload shipments of perishables.

Butter boxes.

Milk shipments.

Low temperature laboratory tests.

The potential uses of DryIce are too numerous to mention. Our laboratories are constantly working out new applications for this wonderful refrigerant.

19. Is DryIce practical for household refrigeration? — One of the outstanding possibilities is the domestic refrigerator, upon which we have done much work. We are not yet ready to put the DryIce household refrigerator on the market. The construction of the present household refrigerator makes it impractical and uneconomical as a container for DryIce.

The DryIce Corporation controls basic patents covering methods of refrigeration with DryIce (solid carbon dioxide) as well as patents issued and applied for on commercial methods of manufacturing of DryIce. The methods and packages as described in this booklet are covered by specific patents issued and pending in addition to the major patents mentioned above.

DRYICE CORPORATION OF AMERICA

50 East 42d Street, New York, N. Y.

Fashionable Use of Dry Ice

Not all the history about dry ice shows an excellent scientific understanding – especially about the dangers of dry ice freezing the skin as a healthful benefit. This article is printed from the Modern Mechanic’s website below, and its comments show that beauty and fad have always been a part of our civilization.